Why "Green" is the Gold Standard: The Secret Science of Herb Drying

Executive Summary: The Science of "Green" Herbs

Why does the color of your dried herbs matter? In herbal medicine, the color of dried herbs reveals their underlying chemistry and signals the presence of beneficial compounds. Bright green dried herbs indicate they still contain plenty of chlorophyll, volatile oils, and active phenols. If herbs turn brown or pale, it means they have oxidized, which destroys their healing power.

At The Naked Botanical, we do more than just use USA-grown herbs. We dry our herbs in a clean room set at 100°F and 35% humidity to keep these important 'bodyguards' from breaking down. For blends, we use a 1/4-inch cut instead of tea-bag dust, so you get the full benefits of the plant.

---

The Industry’s Dirty Secret: Why Most Dried Herbs are Brown

Many people think dried herbs are supposed to be tan or grey, but brown is actually a warning sign. I’ve seen US-grown herbs that turned completely brown, even from trusted wholesalers. Pictured above is lemon verbena from a very reputable herb wholesaler. Lemon Verbena is normally green when dried.

This usually happens when herbs are dried in barns, open-air sheds, or outside, whether in the sun or shade. Alternative, they can be dried in batch dryers at too high of temperature.

A major study on herb preservation points out two big risks with traditional drying methods:

- Sun Drying: UV rays bleach out the color and destroy the medicinal oils.

- Shade Drying: This method keeps the color better, but because it takes days or weeks, herbs can pick up dust, or bird and/or rodent droppings.

The 100/35 "Sweet Spot" for Medicinal Potency

In the past, I have tried every method to dry the herbs. I started drying them inside on screens. This method was adequate, but the herbs didn't dry as quickly and didn't turn out the color I wanted.

At one point, I tried drying the herbs in the oven at the lowest temperature with the door propped open so the moisture could escape. It took a long time, and the herbs were off color.

Then I moved to drying them in our very hot attic with fans. Although the attic dried the herbs well, I was constantly battling humidity that would puff them up. Worse yet, the beginning of September brought cooler night temperatures to the attic, and I had move all the herbs downstairs to dry on screens.

To solve problems like the 'September Cliff,' when cooler weather slows drying, and the 'Rain Trap,' when herbs soak up moisture in attics, we built a special indoor drying room. A 2022 PubMed study found that using controlled, indirect heat helps dry sensitive herbs that are prone to sunlight and maintains their quality.

The Science of the "Powerhouse" (Basil & Mint)

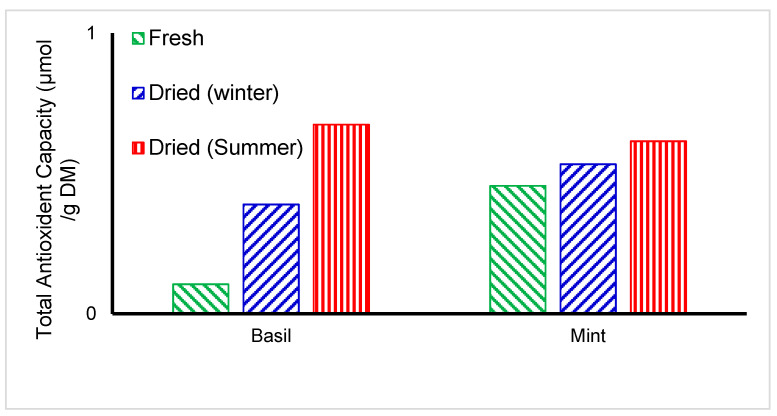

Drying herbs does more than just remove water; it concentrates their valuable compounds. The study’s results by Senka Vidović, et al. were impressive:

Basil (The Antioxidant King): Properly dried basil showed antioxidant capacity 600% higher than that of fresh basil.

Pictured below is the Antioxidant increase of the basil.

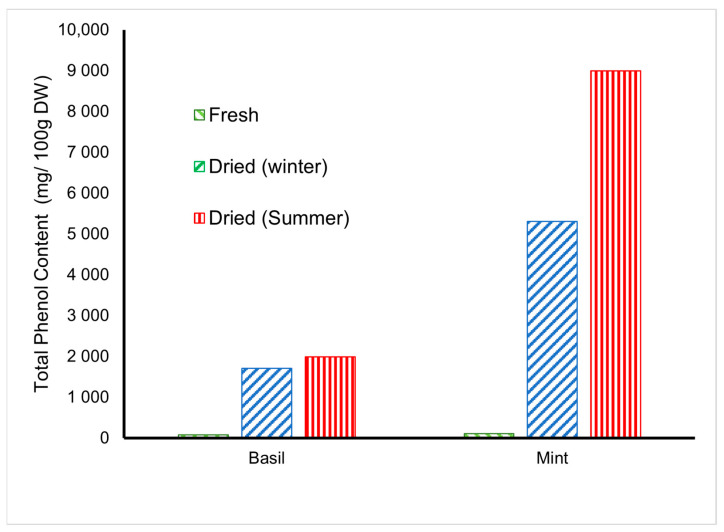

Mint (The Phenolic Powerhouse): Dried mint showed a massive surge in total phenols (the compounds that fight inflammation), reaching nearly 9,000 mg/100g.

Pictured below is Total Phenol Content of the Mint and Basil,

Why This Matters for Your Tea

In our Morning Mojo Herbal tea, we use three types of basil: Sweet Basil, Lemon Basil, and Holy Basil (Tulsi). We also add a form of Mint to every blend. This means you get more than just great taste—you get a strong dose of antioxidants and phenols, which act like natural medicine.

Why We Don’t Sell "Dust" (Fannings vs. 1/4" Cut)

Most tea companies use 'fannings' or dust in their tea bags. Studies show that this fine cut results in the herbs losing their potency quickly. We cut our herbs to about 1/4 inch, which helps keep the essential oils in the leaves.

Before you buy your next jar of herbs, check for these five markers of potency:

1. The Color Test: Is it vibrant green? Green = Medicine.

2. The Cut Size: Look for a 1/4" cut; avoid tea-bag "dust."

3. The Aroma Snap: The scent should hit you immediately.

4. The Processing Origin: Was it dried in a controlled, clean room with heat and dehumidification?

5. The Flavor Cheat: Companies often add natural flavors to create a certain taste. For example, adding dried fruit to tea won’t make it taste like that fruit, so they use natural flavors to get the desired flavor. Read here for more information about natural flavors.

I have one rule: never grind herbs. I always keep them at a 1/4-inch large-cut size. I’ve always felt that cutting the plant too much lets the good stuff escape, and now I have proof.

The Evidence: Why the "Grind" Kills the Medicine

A study in Industrial Crops and Products backs up all the time I cut my herbs to a certain size. The researchers studied what happens when you shred leaves into fine cuts:

- The 13% Loss: In essential-oil-bearing plants, "fine cutting" caused an immediate

-

13% drop in potency. The oils literally evaporated into the factory air.

- Nutrient Wipeout: In certain plants, industrial processing destroyed 100% of the Vitamin C.

- Phenolic Bleeding: When you grind leaves too finely, the antioxidants (phenols) we count on leak out of the plant.

The "Safe Zone" vs. The Cost of Speed

When it comes to drying medicinal plants, there is a fundamental conflict between industrial efficiency and biological integrity.

As early as 1975, researchers such as Maltry et al. established clear "Safe Zones" to preserve the active compounds in plants. For essential-oil species—like the Mint, Basil, and Sage we grow—they recommended a maximum drying temperature of only 95°F to 113°F (35°C to 45°C).

The 120-Hour Truth

Despite these medicinal recommendations, research by Müller points out that in practice, much higher temperatures are often "desired" to slash drying costs. He notes a staggering example: for a plant like Sage, increasing the heat to 140°F (60°C) can reduce the drying time from 120 hours down to just 2 hours.

To a factory manager, a 2-hour turnaround is a victory. To a medicinal herbalist, it’s a disaster.

The "EMC" Trap: Where 50% of the Medicine Vanishes

The data proves exactly why the industrial rush is so costly for consumers. The research revealed a "Trap" at the final stage of drying (known as Equilibrium Moisture Content, or EMC):

- At 140°F (60°C): The plant might look okay while it's still wet, but as soon as it reaches its final dry point, the medicinal oil loss spikes to 50%. *

- At 194°F (90°C), the loss is even more catastrophic, with 90% of the medicine evaporating into the factory vents.

Our Commitment

At The Naked Botanical, we ignore the industrial stopwatch. We strictly follow the medicinal "Safe Zone" by keeping our Clean Room at a steady 100°F.

Whether a harvest takes a day or several to reach its perfect dryness, our goal is never "capacity"—it is preservation. By staying in this temperature window and utilizing our 1/4-inch cut, we ensure that when our herbs reach their dry point, they aren't "hollowed out."

We are protecting that 50% of the soul that the high-heat method burns off, keeping the color, the oils, and the medicine fully intact.

Preserving the "Naked" Integrity

Our rule of using 1/4-inch or larger cuts is essential. By keeping the leaf whole, I am:

1. Protecting the oils: Keeping those volatile oils trapped in the leaf until they hit your cup.

2. Maintaining Integrity: Letting the plant stay whole enough to keep its vitamins, without the crushing that happens in industrial processing or grinding.

When you hold up one of our tea bags and add a teaspoon of our loose tea to your tea cup, you will notice the color difference.

Final Thoughts in Choosing Herbal Products:

Choosing carefully dried, thoughtfully processed herbal products is the key to unlocking their full potential. By seeking vibrant color, whole-leaf cuts, and transparent sourcing, you ensure you’re getting the highest-quality herbs—and the greatest benefits for your well-being. At The Naked Botanical, we’re committed to preserving the integrity and potency of every herb, so you can enjoy nature’s medicine as it was meant to be.

---

Frequently Asked Questions about Medicinal Herbs (FAQ)

Q: Why are some dried herbs green and others brown?

A: Green dried herbs indicate that the plant was dried quickly in a controlled environment, preserving chlorophyll and oils.

Q: Does drying basil increase its antioxidant value?

. A: Yes. This study shows that controlled drying can increase Basil's antioxidant capacity by over 600% by concentrating polyphenols.

Q: What is the best temperature and humidity for drying medicinal herbs?

A: According to the study noted above, the "Goldilocks zone" is between 80°F and 122°F with relative humidity around 35%.

Q: Why are USA-grown and processed herbs safer?

A: I can only speak for myself and fellow herb farmers that I know. I am not aware of "open-air" drying, which can expose plants to birds, rodents, and dust.

---

P.S. Don’t let the 'Three Enemies' steal your herbs’ benefits! We lock in the good stuff, but you need to keep it safe. Heat, air, and light can ruin dried herbs. Watch for our next post on the best ways to store your herbal stash!

References

Al-Hamdani A, Jayasuriya H, Pathare PB, Al-Attabi Z. Drying Characteristics and Quality Analysis of Medicinal Herbs Dried by an Indirect Solar Dryer. Foods. 2022 Dec 19;11(24):4103. doi: 10.3390/foods11244103. PMID: 36553845; PMCID: PMC9777633. https://pmc.ncbi.nlm.nih.gov/articles/PMC9777633/

(2018). WHO guidelines on good herbal processing. World Health Organization. https://www.who.int/docs/default-source/medicines/norms-and-standards/guidelines/production/trs1010-annex1-herbal-processing.pdf

Senka Vidović, Dragoš Cvetković, Milica Ramić, Mirjana Dunjić, Malbaša, R. V., Aleksandra Tepić, Zdravko Šumić, Aleksandra Velićanski, & Stela Jokić. (2013). Screening of changes in content of health benefit compounds, antioxidant activity and microbiological status of medicinal plants during the production of herbal filter tea. Industrial Crops and Products, 50, 338–345. https://doi.org/10.1016/j.indcrop.2013.08.005

Müller, J., et al. (1992). Drying of Medicinal Plants. ResearchGate/WUR eDepot. (Discusses the 120h vs 2h drying trade-off).